New POLISHED STEEL Nib Repair / Burnishing Block with Tools Standard Size.

THIS IS A NEWLY MANUFACTURED POLISHED STEEL BLOCK

THIS IS A HEAVY ITEM. 1kg when packed.

For those of you how wish to repair your damaged nib, here is the essential tool.

Nibs that are bent, twisted or sprung can all be repaired on the block.

This block is manufactured from SOLID GRADE 'A' STEEL giving a hard and smooth surface to work on.

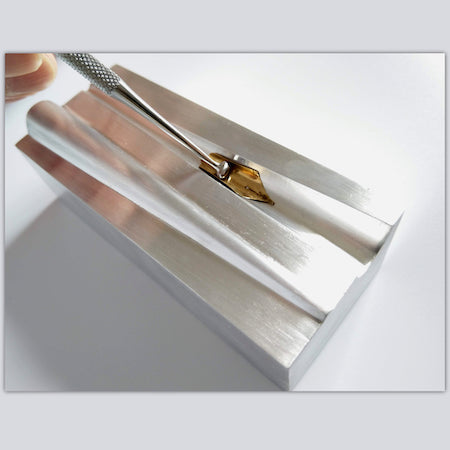

The STEEL Block

2 Diminishing Curves 1 Concave 1 Convex.

4 Assorted Burnishing Tools

This block is manufactured from solid POLISHED STEEL giving a hard and smooth surface to work on.

The block comes with 4 assorted burnisher tools to work with on your nibs.

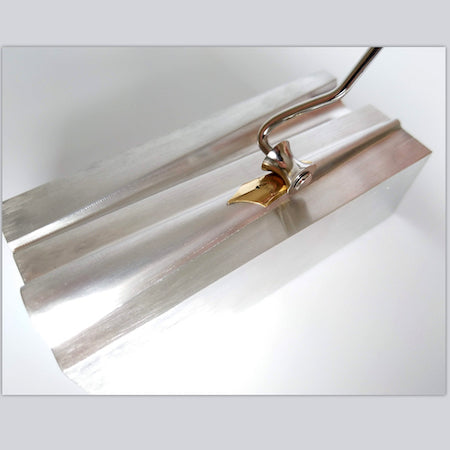

Each of the standard burnishers are 18cm in length.

The roller burnisher is 16cm in length.

Both ends on the standard burnishers can be used

Each end is slightly different giving 6 sizes to use.

Important note, this block is only for the repair of the standard open nib, NOT CONE and CIRCULAR NIBS. e.g. Sheaffer Triumphs, Parker "51" or similar type nibs.

The Block has both Concave and Convex curves for working the underside and top faces off the nib.

The top of the Convex Curve is straight and level as is the bottom of the Concave Curve.

The available area on both surfaces will enable nibs off all sizes to be worked on.

Be aware that over burnishing will result in the metal of the nib hardening and may even become brittle and crack.

Alway make sure that the block is firm to your work surface to prevent slipping while working.

Resting against a stop bar, or on a non slip surface.

Do not let the Roller burnishing tool come into contact with the block surface when working on your nibs as this may change the profile of the nib.

Remember, don't just jump in and start repairing your solid gold vintage nib, practice first with an old nib.

The amount of pressure used to achieve the finished result, will vary depending on the type, material and size of the nib.

It will take time and effort to repair a nib, practice and patience is essential in achieving the end result.